Introduction of VCI Flaky Zinc Coating

What is VCI?

VCI (Volatile Corrosion Inhibitor) technology initiated during World War II and it is mainly used for the protection of weapons and equipment.

Which is suitable for the environments at C5 Category.

VCI is a kind of corrosion inhibitor prepared by special synthesis process and compounding.

It can be directly gasified at room temperature and pressure by itself and adhering to suitable carriers. In the sealed environment, any space gap in the unit will be filled with mixed gas containing VCI rust-proof factor through self-adjustable continuous volatilization. When the gas encounters the metal surface, it will adsorb on it and form a dense protective film with only one or several molecular thicknesses. The protective film can effectively isolate metal surface from contact with water, oxygen and other harmful atmospheric corrosion factors, and inhibit the occurrence of electrochemical reactions to promote metal corrosion, so as to achieve the best anti-corrosion effect.

VCI Sheet Zinc Coating

VCI tech. + Flaky Zinc tech.

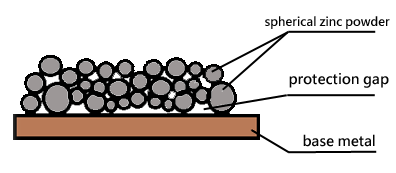

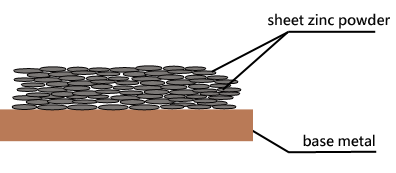

Flaky zinc technology (Patented technology) – It breaks through the tackle of adding flaky zinc powder into the products, grinding common spherical zinc powder into flaky zinc powder and adding special additives in the process of ball milling, in order to realize the uniform dispersion of flaky zinc powder in resin system, thus achieving the goal of high efficiency and anti-corrosion.

HDG v.s. VCI

| Item | Hot-dip galvanizing | VCI Flaky zinc coating |

|---|---|---|

| Resistance to salt & fog | 300-400h(65μm) | 1000-1500h(45μm) |

| Appearance | Burr and inconsistent color | High appearance finish and good overall effect |

| Colors | Zinc white (Only) | Various colors or tailor-made |

| Energy saving & environmental protection | Discharge of waste acid, waste water and waste gas | Dust is produced during shot blasting but can be disposed of by a recovery device |

| Coating hardness | Good | >4H |

| Weather resistance | Turn dark grey after one year | There was no significant change in 5 years |

| Construction site and Maintenance | Aluminum powder paint is used to repair damaged or rusted products. The corrosion resistance life is usually 1-2 years. |

Repair of VCI self-spraying tank can ensure service life of more than 5 years and sustainable maintenance. |